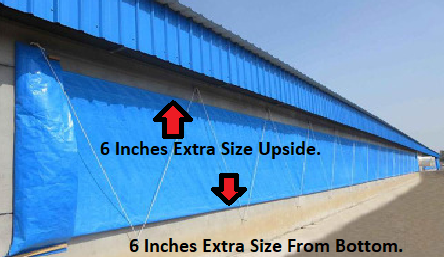

Fogging System Keep your Poultry farm Cool & Keep your birds away from extra heat. So Mortality due to heat stroke gets very less.

Some Precaution You Should Take, if you use Fogging Systems at your Poultry farm.

An automatic drain valve should be installed on each line to drain the water to the outside of the house when the pump is off. By this Drain valves prevent dripping when the system is not in operation.

The pump should be controlled by both temperature and humidity.

Foggers should start running at 28 °C (82 °F).

Low pressure fogging systems operate at 7-14 bar (100-200 psi) producing a droplet size greater than 30 microns.

High pressure fogging systems operate at 28-41 bar (400-600 psi) producing a droplet size of 10-15 microns. This works better in high humidity conditions.

The inlet area nozzles should be positioned where the air velocity is under 600 ft. /min to prevent floor and bird wetting.

Complete Poultry Training – Link

If the mist from one nozzle combines with that of the next nozzle, It make the drop of water too heavy and drop can make litter wet. This situation will cause high humidity and possibly increase bird mortality at the fan end of the house.

So keep sufficient distance from one Nozzle to another nozzle, so that the mist of one nozzle doesn’t interact with each other.

Generator back is must, because birds get habitual of favourable environment, so if fogger get remain off in high temperature, so keep Generator back for emergency case.